Schrage, Wutra, Floveyor, Kreisel

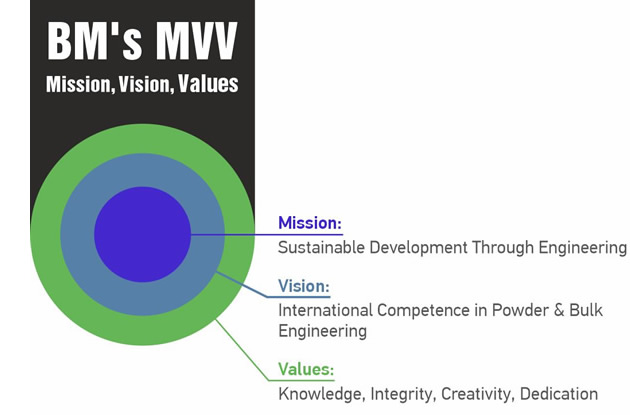

BM Endüstri delivers effective and efficient engineering solutions by combining experience and a broad knowledge base with a strong presence in the international engineering community.

Our philosophy has always been to provide highest customer satisfaction and technical excellence through “good engineering” practices, be it a smallest equipment supply or a complete process design.

Rhewum

Ingetecsa

Jehmlich, Mecaroanne, Gruber Hermanos